Copper concentrates from copper mines is blended with bought out concentrates from other sources and treated to get optimum results. The Smelter is based on a proven energy efficient and environment friendly technology, viz. IsaProcess™ from MIM, Australia, world leaders in Copper smelting technology.

The ISA™ furnace is a vertical shaft type furnace completely lined with refractory into which wet copper is charged along with quartz and limestone into the molten bath. In the process, Copper Concentrate gets converted into two products-Matte, a mixture of sulphide (containing copper and iron), and Slag (Iron Silicate). The mixture of Matte and Slag is then taken to the Rotary Holding furnace where the slag separates out due to differential density. Matte is transferred to Converters for further processing.

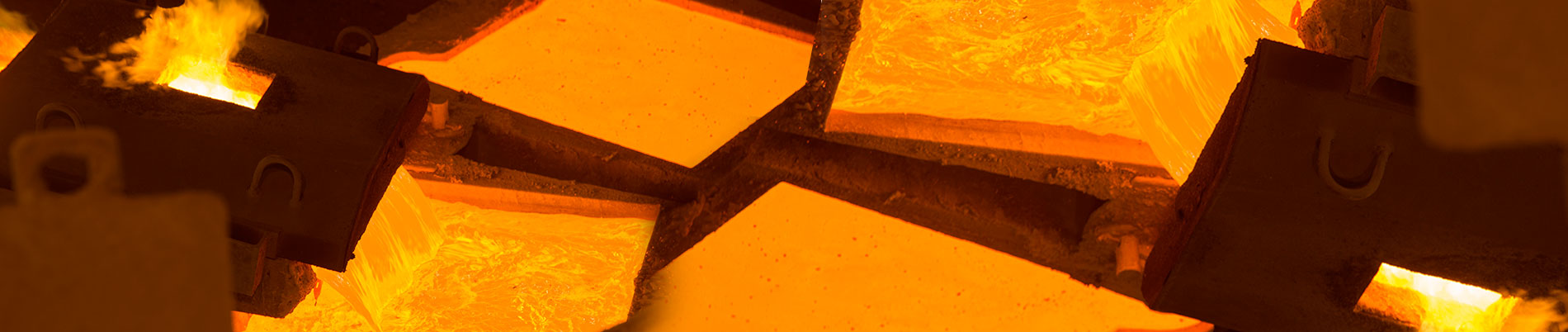

The Copper Matte is converted into Blister Copper in the Pierce Smith Converter in two stages.In the first stage, called Slag Blow, most of the iron and a small quantity of sulphur are oxidised and removed. In the second stage, called Copper Blow, sulphur is removed to get Blister Copper. Converter Slag is treated in a Slag cleaning furnace for recovery of copper. Blister Copper is further refined by oxidation and then by reduction to approximately 99.6% copper purity in the Anode Furnace, and cast as Copper Anodes. Gases produced at various stages are fully recovered and converted into Sulphuric Acid.

Latest Version of CS 3000 Distributed Control System of Yokogawa, Japan controls the entire Copper Smelter. Advance Process Control (APC) implementation methodology involves data collection, approximate candidate controller design, prototype controller design, simulation, testing, and final implementation. APC is implemented to control critical factors like Bath temperature and Lance height control.

The sulphur dioxide gases generated in the smelting process is collected and ducted to the Sulphuric Acid Plant. Set up with basic engineering from Kvaerner Chemetics, Canada, the plant is based on the absorption process known as DCDA, and has a designed capacity to produce (3600) tonnes of sulphuric acid per day.

Sulphuric acid is reacted with rock phosphate in the Phosphoric Acid Plant to produce phosphoric acid. Technology and basic engineering for this plant has been sourced from Hydro Agri International, UK, and the process used is known as Hemi-dihydrate (HDH) Process. The plant has an installed capacity to produce 230,000 tonnes of Phosphoric Acid per annum.

The anode produced by the smelters is processed in the Silvassa and Tuticorin refineries using IsaProcess™ technology sourced from MIM, Australia. The Refineries convert Copper anodes to electrolytic grade Copper cathodes of 99.99% purity. The unique feature of ISA™ refineries is the use of permanent stainless steel cathode plates and its capacity to ensure consistently high operational efficiency and product quality. Electrolysis process deposits pure copper (99.99%) on the stainless steel cathode plates. The impurities and precious metals contained in anodes settle down as anode slimes. Cathodes are then automatically washed, stripped and packed. The material handling equipment is sourced from Wenmec. Continuous monitoring and analysis of refining process through an advanced DCS system ensures close process control. A well-equipped laboratory to test the cathodes for purity and structure of the deposit backs the production facility. A state-of-the-art electrolyte purification plant supplied by Ecotech helps in keeping electrolyte clean and within close limits to get superior quality product and to ensure high operational efficiencies.

An acid purification plant contributes to the purification of the electrolyte, significantly enhancing the quality of the cathodes.

During the electro-refining process, precious metals like gold, silver and Selenium present in the anode settle down at the bottom of the cells along with other impurities. This collection is known as anode slime and it is subjected to atmospheric leaching for recovery of copper — filtered, dried and bagged. The leached slime is exported for recovery of precious metals.

Sterlite Copper is one of two custom smelters in India and set up three continuous cast copper rods units. 2 at Silvasa and 1 at Tuticorin.The Continuous Cast Copper Rod (CCR) Plants are based on technology and equipment from ContinuusProperzi, Italy. The plants have total annual capacity of 240,000 tonnes.

Cathodes are melted in a vertical shaft furnace based on technology from ASARCO, USA. The molten copper is transferred to the casting Wheel through a holding Furnace. Highly accurate measurement and control systems, intrinsic to the Properzi technology, are used to maintain optimum level of molten metal, which is cast into the form of a continuous bar. The continuously cast copper bar is fed into the rolling mill consisting of a unique combination of 2-roll and 3-roll configuration designed to produce excellent quality of rods in different sizes. Online pickling, drying and waxing ensure that the rod is free of oxide scales.

Online scanning with the highly sensitive Defectomat, sourced from Dr Foster, Germany enables freedom from surface defects and ferrous contamination. The process parameter data, online scanning data and results of a battery of off-line tests are captured and processed in the central computer to monitor and control the final quality of the rods. Extensive process control, backed by computerized quality analysis make Sterlite CC Rods highly suitable for Telecom, magnet wire, Transformer, housing wire and cable applications.

Copper rod is coiled in an Orbital laying form to ensure freedom from entanglement while uncoiling by the customers. Each coil is compacted, strapped and wrapped with polyethylene wraps, and stretch-wrapped to prevent contamination with dust and ensure excellent arrival condition at the customer’s end.